The calcium ions will help the alginate strands interlock and create a gel by occupying the spaces between them. You can try alginate cooking at home using these safe and straightforward procedures. To learn more on this, please continue reading below.

Properties of Sodium Alginate

Texture: A rigid, and brittle gel forms in the availability of calcium. As the alginate and calcium concentrations rise, the gel gets stiffer.

Appearance: Transparent when used in cuisine, clear appearance

Temperature (solidified and dissolved): Temperature does not affect this. However, prolonged heating at pH levels that are either too low or too high may cause the gel to destabilize.

Release of flavor: As with most hard-set gels, taste release is poor.

Mouthfeel: Sticky and lingering

Shearing: Breaking down gel

Syneresis: Increase in gel strength

Stable freezing and thawing

Commercial Uses and Food Applications

Food alginates can be used in a variety of ways. It is used in cream, yogurt, ice cream, and cheese as a stabilizer. Ice cream is smoother when it is made with sodium alginate and helps prevent the production of crystals of ice when frozen.

Some of the uses include diffusion-set gels, fruit pulp texturization, protein extrusion, potato storage life extension, usage in structured beef products, enzyme encapsulation, and inclusion in fish patties. To make salad dressings and other prepared foods like puddings, jams, and tomato juices, this ingredient is used.

For bread, noodles, and chilled or frozen items, it is a hydration agent. It creates robust gels when exposed to solutions with acid and calcium. No heat is required for the gel to form. In the spherification process, calcium chloride or calcium lactate make for the most popular substitutes.

As a thickening agent in syrups and sauces, sodium alginate is commonly utilized by food manufacturers. The softening effect of the filling liquid on pastry can be minimized by thickening it with sodium alginate before baking. Thickening using sodium alginate reduces the likelihood that emulsions of water and oil, including certain salad dressings and mayonnaise, break apart.

Uses of Alginate in Cooking

Spherification

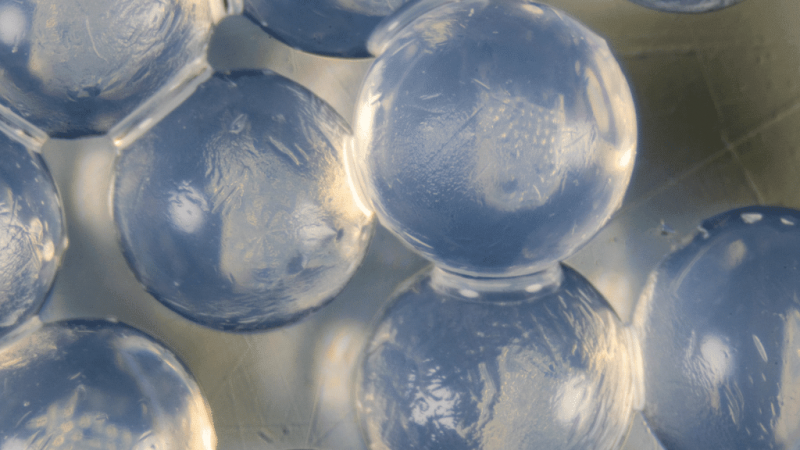

Spherification is a method first popularized by Ferran Adria at El Bulli and is the most prominent use of this substance in molecular gastronomy or culinary physics. Spherification is a culinary technique for creating caviar-like spheres out of a liquid.

Scientific ideas can be applied to cooking and baking in the form of Culinary Physics, often clubbed with molecular gastronomy. Ferran Adrià recreated caviar by dissolving sodium alginate in the solution of calcium with fruit juice. It turns out to be a liquid when the proper quantities are combined before adding to the calcium solution. Proceeding in terms of drops, the liquid is injected into the calcium solution with a spoon, resulting in a gelatinous covering around the drops that resemble caviar.

Yogurt and Drinks Based on Dairy

As a stabilizing agent, sodium alginate is becoming to be found in eggnog, chocolate milk, fruit-flavored options, or yogurts.

Cheese with Sodium Alginate

Soft cheese spreads can benefit from a small amount of the substance to minimize oil and water separation, reduce the hardening of the surface, and create processed cheese with a better texture. Sodium alginate acts as a thickener in whipped cream. Adding alginate to synthetic creams can speed up whipping time, increase tolerance for over-whipping, regulate overrun, and minimize syneresis.

Sodium Alginate in Popsicles as well as Ice Cream

In ice creams, sodium alginate is employed as a thickening agent to prevent ice crystals from forming, thus ensuring a creamy texture. The use of sodium alginate in fruity flavored popsicles ensures that the fruit is evenly distributed during the process of freezing and prevents them from spilling while being consumed.

Toppings, Beverages, Salad Dressings, and Fillings – all use alginates

An alginate-based icing is non-sticky and avoids cracking. Aside from keeping foamy or aerated constructions stable, alginates can also be used to enhance the texture of items like whipped-sugar toppings. Jellies made with alginates are more stable at higher baking temperatures, thereby reducing syneresis.

Alginate–phosphate blends can be used to stabilize chocolate milk. Stabilized acidic drinks are made from a mixture of vegetable extract, juice, and milk products by combining a fatty acid ester and polyol alginate with pectin.

Dessert Gels that Contain Water

Alginates can be used to create attention-grabbing edible gels. Cross-linking with calcium is common, although other cations, such as divalent as well as trivalent metal ions, can be used. To better regulate reaction rates and product texture, pH and calcium ion concentration should be adjusted to neutral. A gel that gels too quickly has a gritty texture, whereas a gel that gels too slowly has a very soft texture. The solubility of the calcium ions must be managed with appropriate salt and retarding agents, resulting in a controlled calcium ion release.

FAQs

What is the best method for adding Sodium Alginate to a liquid?

Sodium alginate dissolves, hydrates, and gels readily in a wide range of liquid temperatures, although it melts at temperatures exceeding 266°F (130°C).

However, it is best to gradually add the sodium alginate powder to the liquid, using an immersion blender or whisk, until the desired consistency is achieved. Small lumps will appear in the solution if the alginate is not thoroughly disseminated. Avoid over-whisking the thickened solution, as air bubbles can become trapped. Allowing the mixture to rest in the refrigerator for a few hours may help prevent the formation of air bubbles that could impede the spherification process.

Is there an ideal ratio of Sodium Alginate to water?

To some extent, how much sodium alginate you’ll require depends on the application.

Direct Spherification:

A 0.5 percent to 1 percent sodium alginate base and a 0.5 percent to 1 percent calcium lactate setting bath are utilized for direct spherification. The higher the viscosity of the liquid inside the gel sphere, the more sodium alginate was initially added to the base.

Reverse Spherification:

Sodium alginate with a calcium lactate base of 2 percent is utilized in reverse spherification. The sodium alginate 0.5 percent is now added to the bath rather than the base as in the direct spherification method.

Is it safe to consume sodium alginate?

Yes, sodium alginate is completely safe to eat (even in relatively high amounts). However, just a small amount is required to act as an emulsifier. As a result, you can safely consume far more than you would ever consume.